Akshit

Technical Projects

Some of the recent technical projects I have conceptualized, designed, executed and perfected over the last few years.

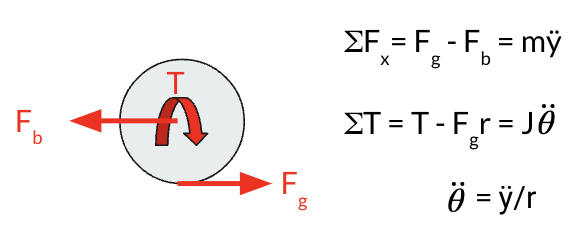

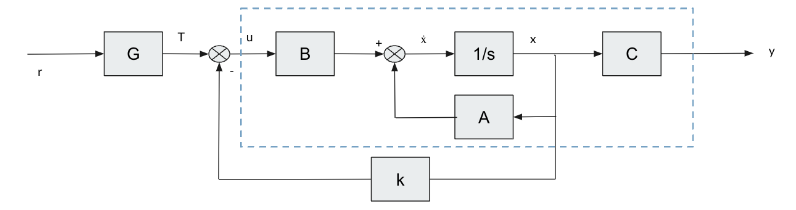

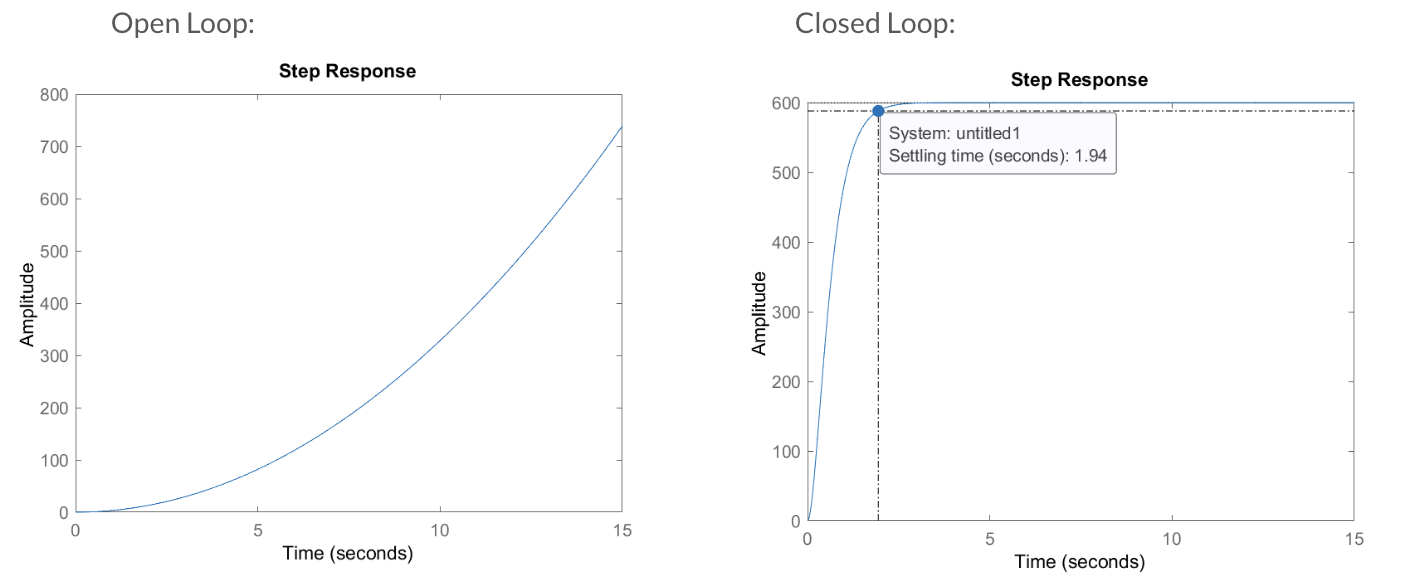

Controller Design of a Driven Cart - Fall 2022

Conceptualized a real-world model for a driven cart, surveyed the parameters of the system and devised a controller with near zero overshoot and 2 seconds of settling time. The major challeges faced were real-world implementations and design decisions that were impacted due to external factors, with the next steps of the model clearly laid out as tackling those and handling more intricate inputs such as angular shift of the gas pedal while also accounting for motor limitations.

Here are some of the screenshots of the results that were obtained from this model:

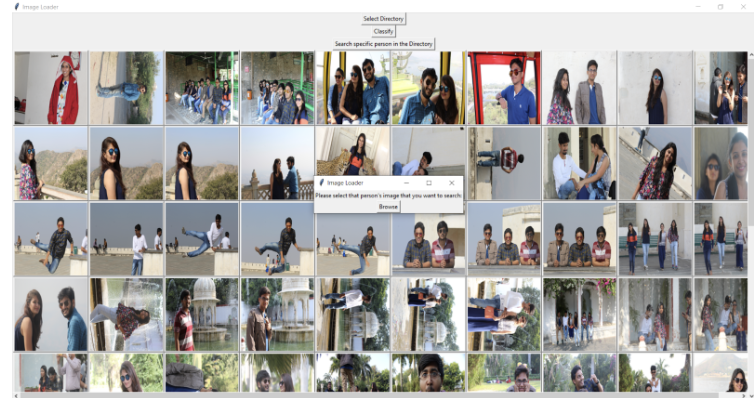

Machine Learning for Picture Gallery - Fall 2022

Conceptualized a fully deployable picture gallery with a responsive UI with face recognition and an offline implementation, using Python. The main criteria for this project was to have a fully offline version fo a smart gallery, where face recognition could be done with verifiable accuracy and with a good response time, as it has potential to have great value uses for security, spam filtering, ease of use among all else.

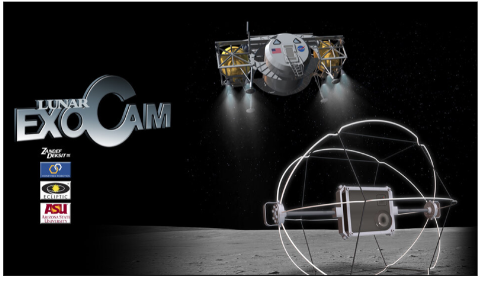

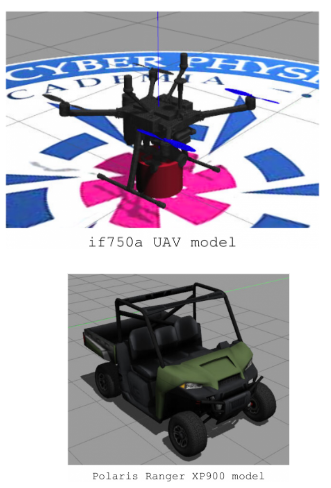

2021 NSF CPS Challenge - Spring 2022

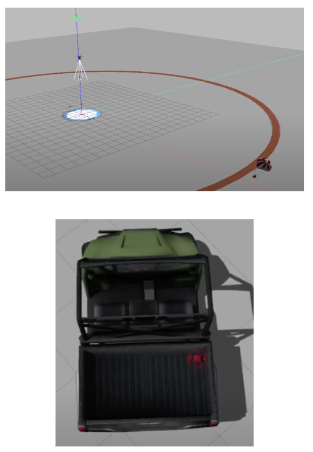

The NSF CPS Challenge was an amazing experience and a great opportunity to learn and put some of my core Robotics skills into a well-designed and intriguing challenge. It comprised of 4 phases, each requiring further implementation in ROS2, Gazebo and OpenCV. The ultimate task was to launch a projectile using a drone into the trunk of a moving car, which was accomplished with diligent effort and perseverance.

Here are some of the screenshots of the results that were obtained from this model:

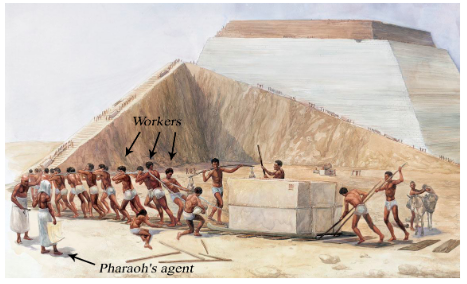

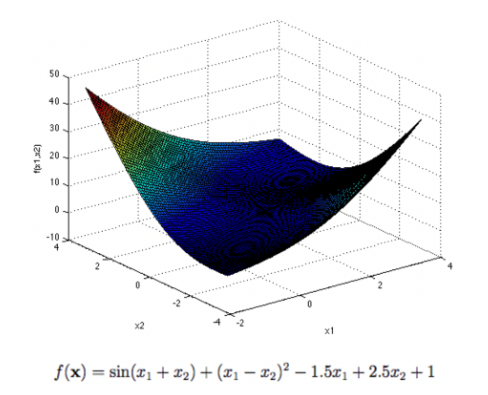

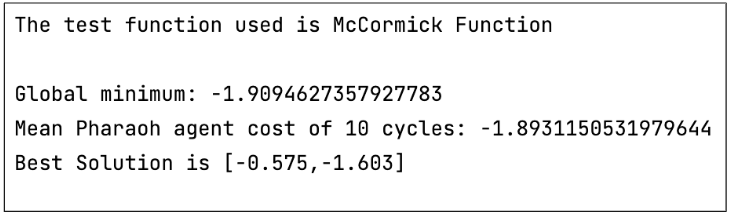

Giza Pyramid Construction (GPC) - Spring 2022

Giza Pyramid Construction (GPC) algorithm was another ML technique and algorithm that was programmed and reviewed to test various standardized functions, yielding exemplary performance and providing insight into ancient-inspired algorithms.

Here are some of the screenshots of the results that were obtained from this model:

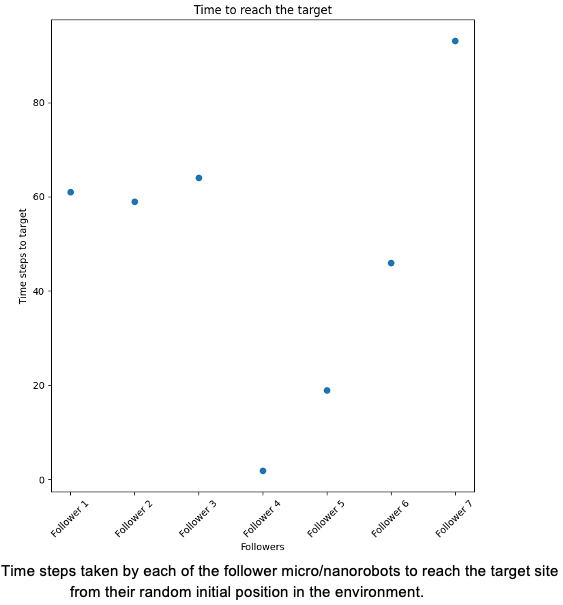

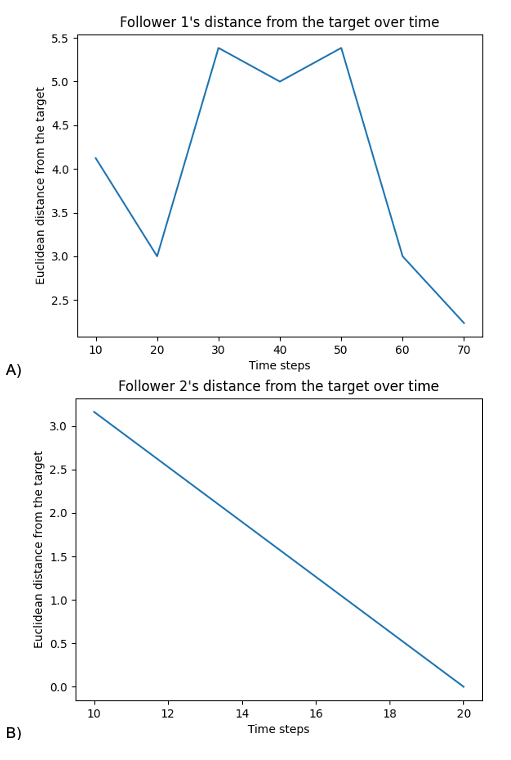

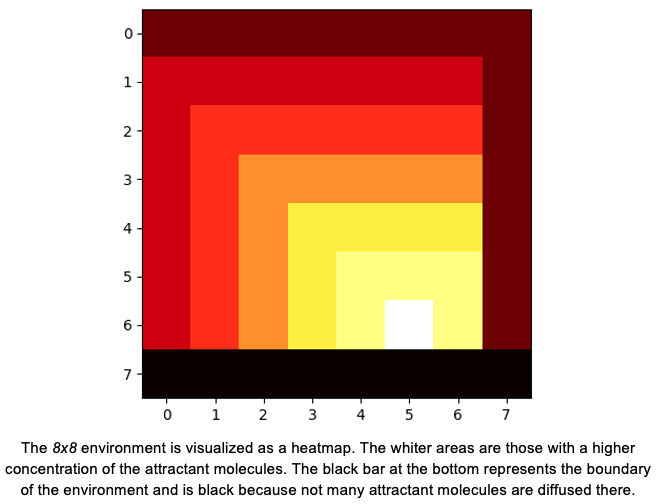

Targeted Drug Delivery By Nanorobots Using Chemotaxis - Fall 2021

Targeted drug delivery is a new application of micro/nanorobots. It is particularly exciting because the micro/nanorobots can access almost every tissue of the human body and, thus, be used to deliver drugs to precise locations in precise quantities. This precise delivery of drugs avoids side effects that might be a result of the drugs reaching unintended tissues. A lot of research has been carried out about such drug delivery methods in the past few years. In this project, the leader-follower model of communication was used for targeted drug delivery using micro/nanorobots. First, a mathematical model was developed which dictates how the two types of micro/nanorobots move around. Then, two properties of this model, viz., equilibrium and consensus, were proven. Subsequently, simulations for this model were run in Python 3 and the two possible scenarios were compared.

Here are some of the screenshots of the results that were obtained from this model:

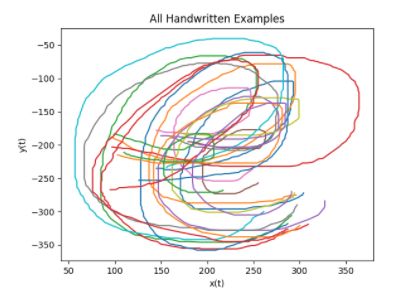

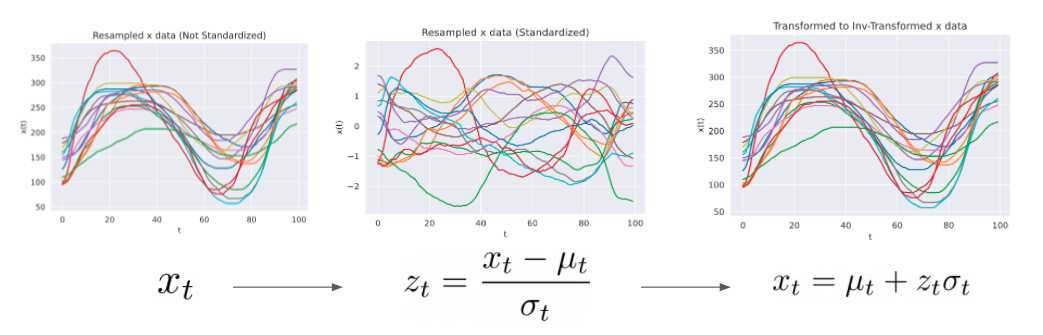

Gaussian Processes for Handwritten Data - Fall 2021

This project employed Gaussian Process Regression to predict time series data, specifically generating a predicted trajectory of a handwritten letter “e”. To accomplish this, the time series data was segmented into the x and y components with respect to time and then rescaled to fit the domain [0,10]. Different kernels were used, squared exponential and rational quadratic, and their results both fitted well. Appropriate observation points are very important for Gaussian regression models. Too few will cause the prediction interval to be wide, and too many will cause the model to overfit. It was observed that Gaussian processes are well equipped to fit such data and can predict with a minimal error rate.

Here are some of the screenshots of the objective, model and the results that were obtained:

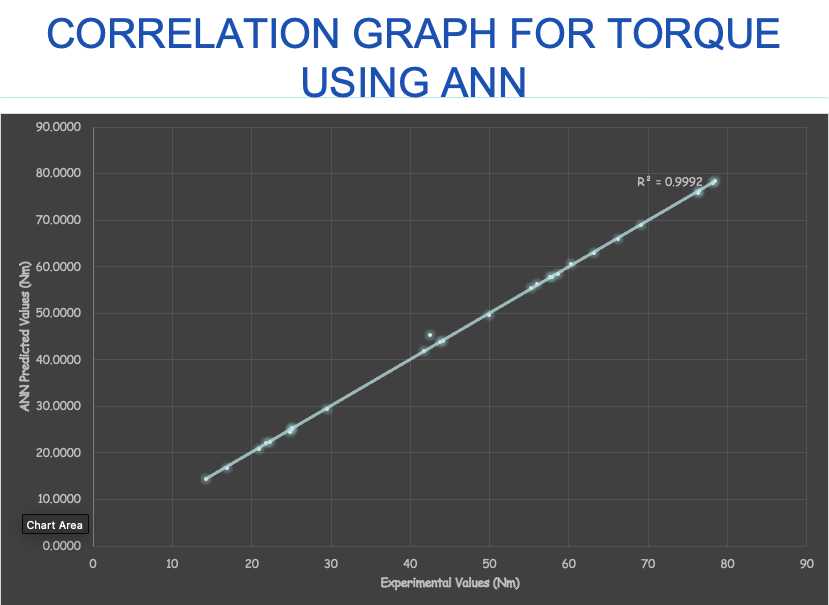

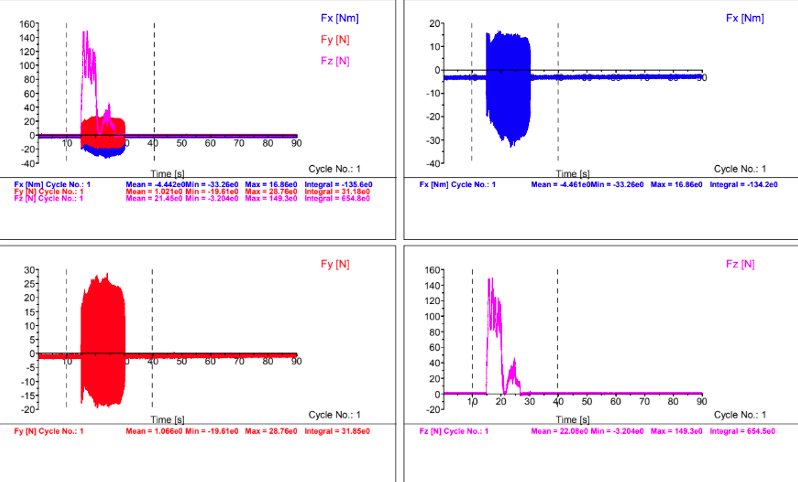

AI Modeling and Drilling Parameters of Nanocomposites - Oct 2019 - May 2020

A carbon fiber composite reinforced with CNT was fabricated and its drilling process was studied. Statistical analysis and Artificial Intelligence modeling were performed to determine optimal machining parameters for this specific composite. Fuzzy Logic and Neural Networks were the techniques that were employed and subsequently tested. Artificial Neural Networks show the best performance in these predictions and can be used to accurately predict Thrust Force and Torque.

Here are some of the images of the drilled composite and the results obtained:

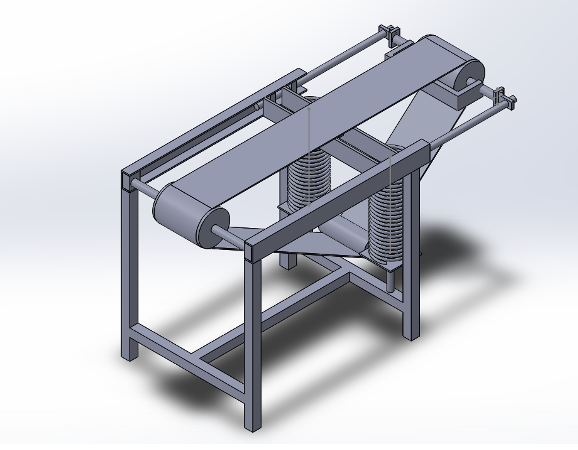

Design and Fabrication of a Portable Conveyor System - Dec 2018 - May 2019

Designed and incorporated a belt conveyor capable of adjusting length using an idler pulley and spring setup, to enable reconfigurability and portability.

Here are some of the pictures of the CAD model and the constructed prototype: